Maximizing Manufacturing Efficiency with Automation & Controls Engineering

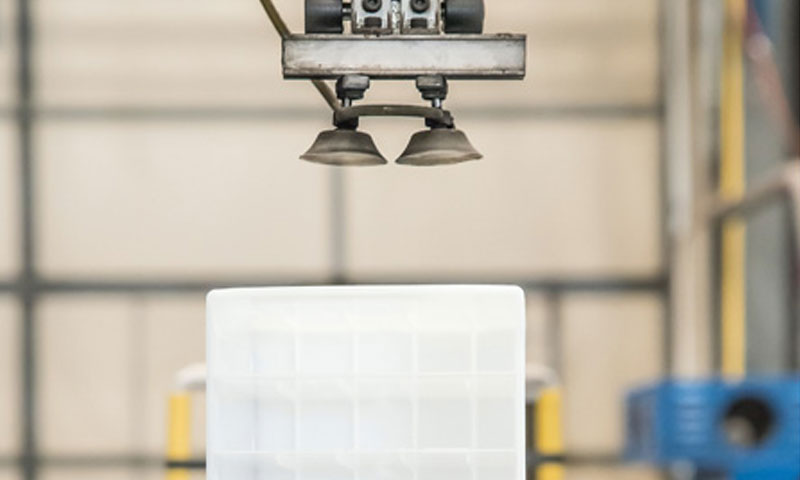

In today’s fast-paced industrial world, manufacturers are under constant pressure to do more with less—less time, less labor, and less risk. For companies in highly regulated and production-intensive industries like life sciences, food & beverage, and specialty manufacturing, the key to staying competitive lies in one powerful concept: automation and controls engineering.

At e2i, we help businesses unlock their full operational potential by designing, integrating, and optimizing automation systems that reduce downtime, improve product quality, and support scalable growth. In this blog post, we’ll explore how automation and controls engineering delivers real, measurable value across industries and how e2i’s tailored approach helps you stay ahead.

What Is Automation and Controls Engineering?

Automation and controls engineering is the backbone of modern industrial operations. It involves the design and implementation of systems that control equipment, monitor processes, and automate repetitive tasks.

These systems typically include:

- PLC Programming (Programmable Logic Controllers)

- HMI Design (Human-Machine Interfaces)

- SCADA Integration (Supervisory Control and Data Acquisition)

- Data Historian Configuration and Reporting

- Instrumentation and Sensor Integration

When done right, these components work together to ensure that your processes run smoothly, safely, and efficiently—every time.

Why Automation Matters in Regulated and High-Output Industries

Industries like pharmaceutical manufacturing, biotech, chemical processing, and food & beverage operate under strict compliance guidelines while managing high-volume production. That means the stakes are high—one misstep can lead to costly recalls, downtime, or regulatory consequences.

That’s where automation delivers its strongest ROI:

- Reduced Human Error: Automated controls ensure consistency in product quality and process adherence.

- Improved Throughput: Systems can run faster and more reliably than manual operations.

- Regulatory Compliance: Automated data capture and audit trails support FDA, USDA, or cGMP documentation requirements.

- Scalable Operations: Easily replicate systems across new lines, facilities, or product expansions.

How e2i Delivers Best-in-Class Automation and Controls Engineering

At e2i, we don’t believe in one-size-fits-all solutions. Every system we design is purpose-built for your facility’s goals, equipment, and regulatory environment.

Our comprehensive services include:

Custom PLC Programming

We work with major platforms like Allen-Bradley ControlLogix, Siemens, and GE to develop PLC logic that’s optimized for your exact process—from clean-in-place (CIP) systems in pharma plants to packaging lines in food processing facilities.

HMI and SCADA Interface Design

We build intuitive, user-friendly interfaces with platforms like FactoryTalk View SE, Ignition, and Wonderware to give operators full visibility and control over their process—reducing training time and operational risk.

Data Acquisition & Historian Integration

Our systems capture critical performance and compliance data and integrate it into your data historian for real-time visibility, trend analysis, and batch reporting.

Testing, Qualification & Support

e2i provides full testing and qualification support in both offline simulation and production environments. We also write and execute automation test cases and develop standard operating procedures (SOPs) and training programs.

Case in Point: Automation Upgrade for Pharmaceutical CIP Systems

A recent project at a pharmaceutical formulation and filling facility required e2i to overhaul the automation system for two Clean-in-Place (CIP) units. By modifying the PLC and HMI code, adding recipe downloading, and integrating shared feed tanks, we not only improved operational efficiency but also reduced changeover time and supported new product lines—all while maintaining compliance with stringent industry regulations.

The Bottom Line: Automation Is Not a Luxury—It’s a Necessity

Whether you’re upgrading legacy systems, scaling your operations, or improving compliance, automation and controls engineering is the key to long-term success. With e2i’s industry expertise and client-first approach, we’ll help you design and implement smart, efficient systems that grow with your business.

Ready to Automate Smarter?

Let’s talk about how e2i can help transform your facility with custom automation and controls engineering solutions.

Contact us today to schedule a consultation.