The Critical Role of Automation Testing in Regulated Manufacturing Environments

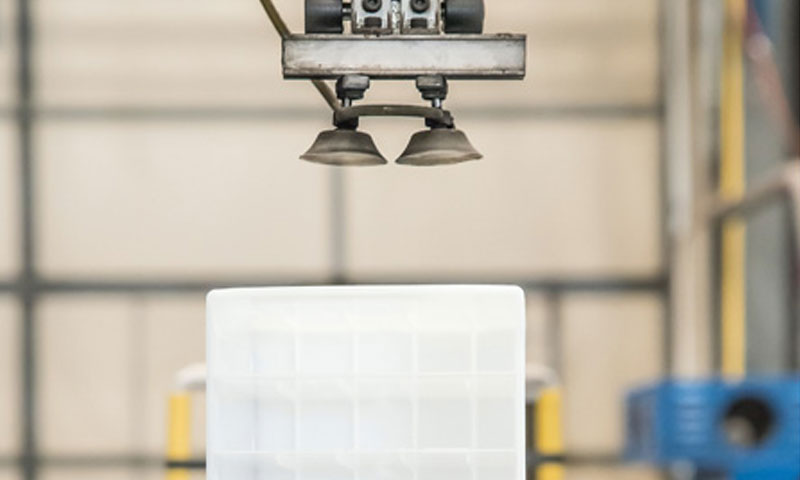

In highly regulated industries such as pharmaceuticals, biotech, and food and beverage, automation testing play a vital role in production consistency, product safety, and regulatory compliance. But simply installing a new control system isn’t enough—it must be thoroughly tested and validated to prove that it functions reliably, safely, and within specification.

That’s where automation testing becomes a mission-critical activity.

In this post, we’ll explore why automation testing is essential, what it involves, and how companies like e2i help ensure that automated systems are ready for production—and inspection—without surprises.

Why Automation Testing Matters

Automation is only as strong as its weakest function. A missed interlock, a miswritten PLC instruction, or a faulty alarm could lead to:

- Batch failures

- Product recalls

- Downtime

- Regulatory violations

- Unsafe operating conditions

In FDA-regulated industries especially, systems must not only work but must be proven to work through documented testing.

What Does Automation Testing Involve?

Effective testing encompasses much more than just running the HMI and pushing buttons. It typically includes:

1. Requirements-Based Testing

All test cases should trace back to system design and functional requirements. This ensures that every control sequence, alarm, and interlock was built for a purpose and verified for accuracy.

2. Offline (Simulated) Testing

Before live commissioning, engineers can test control logic and HMI functions in a virtual or offline environment. This minimizes disruption to production and helps catch logic errors early.

3. Factory Acceptance Testing (FAT)

FATs validate that the system performs as expected before it’s shipped to the production site. This is a key milestone for system integrators and clients.

4. Site Acceptance Testing (SAT)

After installation, SAT ensures the system works correctly in the live plant environment with real equipment, sensors, and inputs.

5. GAMP-Compliant Validation

For regulated environments, testing must align with Good Automated Manufacturing Practice (GAMP) principles. This includes formal documentation such as:

- IQ (Installation Qualification)

- OQ (Operational Qualification)

- PQ (Performance Qualification)

Key Benefits of Automation Testing

Regulatory Compliance

Testing provides documented proof that systems meet FDA, USDA, or other applicable standards.

Risk Reduction

Identifies and eliminates software bugs, logic errors, or hardware integration issues before they impact production.

Operational Efficiency

A properly tested automation system results in fewer disruptions, faster changeovers, and more reliable data for decision-making.

Improved Operator Safety

Verified interlocks and alarms help protect operators and equipment by preventing unsafe conditions.

A Real-World Perspective: How e2i Supports Testing Projects

At e2i, we regularly support clients who are repurposing existing facilities or installing new process lines. Our automation engineers work from requirements gathering through testing execution, writing and executing test cases in:

- Offline emulation environments

- Factory and site acceptance tests

- Validated production settings

We also develop comprehensive documentation for GMP audits and support training and SOP development to ensure smooth adoption by plant personnel.

Industries That Benefit Most from Automation Testing

Automation testing is vital across sectors but especially crucial in:

- Pharmaceutical formulation and filling

- Biotech fermentation and purification

- Medical device manufacturing

- Food and beverage process control

- Nutraceutical and personal care production

Any facility that must prove system performance to regulatory authorities can benefit from a robust automation testing strategy.

Final Thought: Don’t Just Automate—Validate

Modern manufacturing depends on automation, but compliance and performance depend on proving that automation works—consistently and safely. Comprehensive automation testing is the bridge between implementation and real-world readiness.

For companies operating in regulated spaces, investing in thorough, traceable automation testing isn’t just a best practice—it’s essential.