Validation & Compliance Services: Safeguarding Quality in Regulated Manufacturing

Ensuring Quality and Compliance Through Expert Validation Services

In regulated industries like pharmaceuticals, biotech, and food processing, compliance isn’t just a checkbox—it’s the backbone of your operations. From FDA audits to GMP requirements, your facility must operate within strict guidelines that demand documentation, traceability, and unwavering quality. That’s where validation and compliance services from e2i become a critical asset.

At e2i, we support companies in meeting regulatory standards with custom validation protocols, GxP-aligned processes, and thorough documentation that reduce risk, prevent costly delays, and get your products to market faster.

What Are Validation and Compliance Services?

Validation and compliance services refer to the planning, execution, and documentation of tests and protocols that verify whether equipment, processes, and systems perform as intended—and remain in compliance with regulatory standards.

Our services typically include:

- Commissioning & Qualification (C&Q)

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification (PQ)

- Risk Assessments & Traceability Matrices

- Validation Master Planning

- GAMP 5 Documentation Support

Why Validation Matters in Regulated Manufacturing Environments

In industries governed by FDA, EMA, or other global health authorities, validation ensures that your systems are not only functioning correctly, but that they do so consistently and safely. It’s also a critical part of Good Manufacturing Practice (GMP) compliance.

The benefits of strong validation processes include:

- Regulatory Readiness: Be prepared for audits with complete, accurate documentation.

- Product Quality Assurance: Confirm that products meet defined specifications.

- Risk Mitigation: Identify and address issues early before they become expensive problems.

- Accelerated Time-to-Market: Avoid delays with clear qualification pathways.

- System Reliability: Ensure ongoing operational consistency.

e2i’s Approach to Validation and Compliance

Unlike firms that treat validation as a formality, e2i integrates compliance from the ground up. Whether you’re installing a new production line, updating automation systems, or repurposing a facility, we bring deep regulatory expertise and hands-on experience to every project.

Full Lifecycle Validation Support

From design through to operational use, we validate entire systems—mechanical, automation, and procedural. We help you map user requirements to functional design and verification testing through URs, FRS, DS, and V&V documents.

Customized Protocol Development

No copy-paste documents here. We create IQ, OQ, and PQ protocols tailored to your exact equipment, software, and production needs, ensuring you meet both internal SOPs and external compliance mandates.

Risk-Based Validation

We prioritize critical systems and functions using risk assessments and impact analyses to allocate resources efficiently—aligned with ISPE Baseline Guides and GAMP 5 principles.

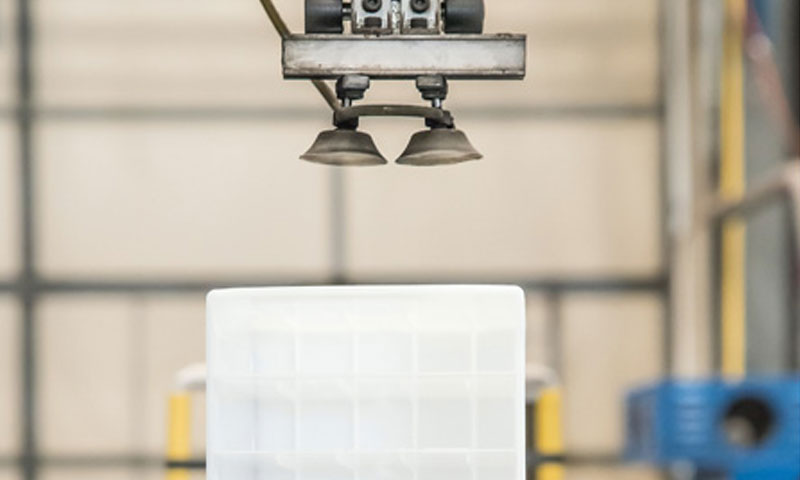

Hands-On Execution & Testing

We don’t just write protocols—we execute them. Our engineers work on-site and in offline environments to test systems, troubleshoot issues, and finalize qualifications with minimal production disruption.

Validation Is an Investment in Confidence

When your business operates in a high-stakes regulatory environment, you can’t afford shortcuts. Partnering with a proven provider like e2i ensures that every piece of your operation—from automation to documentation—is aligned, auditable, and ready for inspection.

Whether you’re building new systems, upgrading existing ones, or returning to a validated state after a change, our validation and compliance services offer peace of mind and a clear path to success.

Let’s Get Started

Need help navigating the complex world of regulatory validation? e2i is here to support your team every step of the way.

Contact us today to learn more about our validation and compliance services.