Optimizing Clean-in-Place (CIP) Systems for Efficient, Compliant Manufacturing

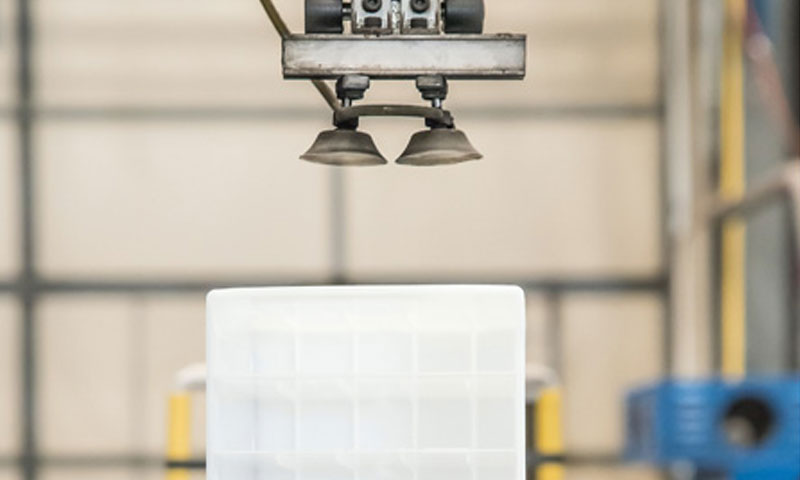

In high-stakes industries like pharmaceuticals, biotech, and food & beverage, Clean-in-Place (CIP) systems are critical for maintaining product quality, regulatory compliance, and operational efficiency. Optimizing CIP systems ensures that process equipment is thoroughly cleaned between batches—without needing to disassemble machinery or halt production for long periods.

But here’s the challenge: many CIP systems are outdated, inefficient, or poorly integrated into broader manufacturing processes, leading to excessive downtime, water and chemical waste, and audit vulnerabilities. That’s where smart automation and thoughtful optimization come into play.

Why Optimizing CIP Systems Matters

CIP systems often operate in the background—until they don’t. When a cleaning cycle fails or takes too long, it can:

- Delay production schedules

- Waste high-purity water or expensive cleaning agents

- Compromise product quality or safety

- Create noncompliance risks during inspections

Whether you’re expanding product lines, repurposing equipment, or simply looking to improve operational performance, CIP optimization can offer fast and measurable ROI—especially when paired with automation and data integration.

Key Areas of Optimizing CIP Systems

1. Cycle Time Reduction

Outdated or overly conservative CIP recipes often run longer than necessary. By analyzing flow rates, temperature curves, and cleaning effectiveness data, manufacturers can safely reduce cycle durations without compromising hygiene standards.

Result: Faster batch turnaround and reduced cleaning bottlenecks.

2. Automated Recipe Management

Manually controlled or hard-coded CIP systems are prone to error and inflexible when processes change. Upgrading to recipe-based automation—a service e2i regularly provides—allows facilities to adapt cleaning parameters for specific equipment, products, or contaminants.

Benefits include:

- Repeatable, validated cleaning performance

- Easier updates when new products are introduced

- Improved regulatory traceability

3. Data Collection and Reporting

A compliant CIP system must prove it did what it was supposed to do—every time. Integrating the CIP system with a data historian or batch reporting system enables automatic logging of:

- Start/end times

- Temperatures and flow rates

- Conductivity or chemical concentration

- Cycle status and alarms

This data supports audit readiness, deviation tracking, and continuous improvement initiatives.

4. Utilities Optimization

CIP systems consume large amounts of:

- Water for Injection (WFI)

- Purified Water

- Steam

- Cleaning chemicals (acids, bases)

Through system analysis, flow control tuning, and smarter sequencing, many facilities can significantly cut their utility costs. For example, switching from time-based rinses to conductivity-based endpoints can reduce water use without compromising cleanliness.

5. Safety and Interlocks

Properly designed interlocks prevent:

- Cross-contamination

- Over-pressurization

- Human error during setup

When retrofitting or upgrading CIP systems, it’s crucial to incorporate safety logic, alarms, and fail-safes—especially when CIP equipment shares common tanks or feeds multiple skids.

Industry Applications: Who Benefits Most?

CIP optimization is especially relevant to:

- Pharmaceutical formulation and fill-finish plants

- Biotech fermentation facilities

- Food and beverage processing lines

- Dairy and brewery operations

- Nutraceutical and supplement manufacturers

Whether driven by a regulatory inspection, new product introduction, or a lean manufacturing initiative, optimizing your CIP process supports both compliance and profitability.

A Real-World Approach: How e2i Supports CIP Projects

At e2i, our team supports CIP optimization from design and automation to validation and reporting. We’ve worked with clients repurposing formulation facilities for new products, integrating shared utility systems, and modernizing legacy PLCs and HMIs to support recipe downloading, data logging, and GMP compliance.

We develop:

- Automation design and testing documentation

- Validation protocols (IQ/OQ/PQ)

- Operator SOPs and training materials

- Custom batch reports using historian data

Final Thoughts: Clean Smarter, Not Just Harder

Your CIP system shouldn’t be a hidden drain on your production capacity and operating costs. With modern automation and data-driven optimization, it’s possible to clean faster, safer, and smarter—while meeting the rigorous standards of the FDA, USDA, and other regulatory bodies.

If you haven’t evaluated your CIP system recently, it may be time to ask: Are we cleaning for compliance or just cleaning out of habit?