Improving Clean-In-Place (CIP) Systems with Automation and Data

In sanitary manufacturing environments—such as food, beverage, dairy, cosmetics, and pharmaceuticals—Clean-In-Place (CIP) systems are essential for maintaining hygiene, ensuring product safety, and meeting compliance standards. However, traditional CIP processes often rely on manual steps, limited data visibility, and inconsistent execution, which can lead to inefficiencies, validation risks, and increased downtime.

At e2i, we help facilities modernize their cleaning operations through CIP system automation, integrating recipe-based control, real-time monitoring, and centralized data logging to create a more repeatable and compliant process.

In this article, we explore how automation transforms CIP performance and what best practices can make the difference between a good system and a truly optimized one.

What Is a Clean-In-Place (CIP) System?

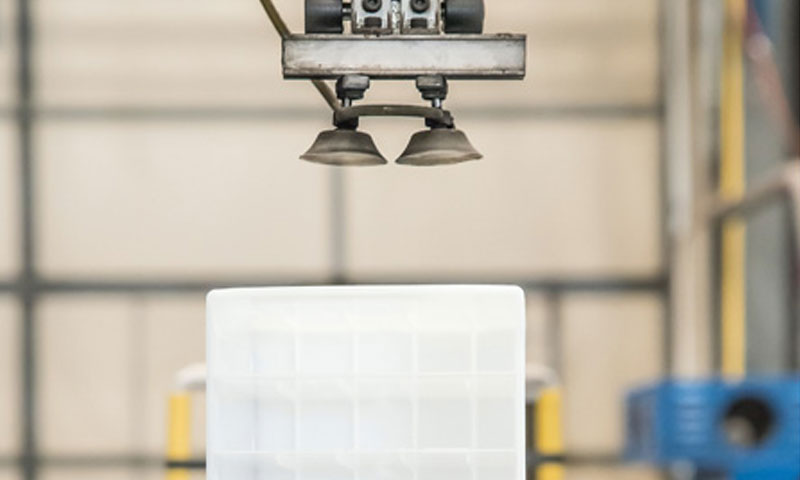

A CIP system enables the automated cleaning of processing equipment—including tanks, pipes, and valves—without disassembly. These systems are critical in industries where hygiene standards are tightly regulated and product changeovers are frequent.

Traditional CIP systems rely on programmed rinse and wash cycles using water, chemicals, and steam. However, without automation and proper data collection, it’s difficult to guarantee repeatable results or prove that the process meets regulatory requirements.

Why Automate CIP Systems?

CIP system automation eliminates guesswork and variation by standardizing cleaning steps and collecting performance data. Automated systems can be configured to:

- Reduce water and chemical waste

- Minimize cleaning time and downtime

- Enforce validated cleaning sequences

- Provide digital records for compliance audits

- Enable centralized monitoring of multiple tanks and loops

For facilities running 24/7 production schedules, the ability to clean quickly and consistently without compromising quality or compliance can have a significant impact on efficiency and cost.

Core Elements of Automated CIP Systems

Recipe-Based Control

One of the most impactful upgrades in CIP system automation is implementing recipe control. With automated recipe management, specific cleaning procedures can be created, stored, and executed for each product line, tank, or piece of equipment.

Recipes include:

- Pre-rinse, wash, and post-rinse sequences

- Flow rates, temperatures, and chemical concentrations

- Hold times and step verification logic

- Interlocks to ensure equipment is properly isolated

This ensures that each cleaning cycle is consistent, repeatable, and validated according to your standard operating procedures (SOPs).

Shared Tank and Loop Optimization

Many facilities operate multi-loop CIP systems with shared tanks and distribution lines. These configurations offer cost savings but require careful coordination to prevent cross-contamination or downtime.

e2i helps clients:

- Automate shared tank scheduling and prioritization

- Configure valve matrix logic for safe line switching

- Coordinate cleaning with production availability

- Minimize idle time between cycles

Through programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems, we ensure shared CIP resources are used efficiently without compromising cleaning integrity.

Data Logging and Compliance Reporting

Automated CIP systems also support real-time data logging, which is essential for both operational performance and regulatory compliance.

e2i designs systems that track:

- Start and end times of each CIP phase

- Flow rates, temperatures, and chemical concentrations

- pH and conductivity levels

- Deviations and operator interventions

This information is recorded and stored for reporting, trend analysis, and audit readiness. For FDA-regulated facilities, data integrity and traceability are key components of a validated cleaning process.

Integration with SCADA and Batch Systems

Modern CIP systems don’t operate in isolation—they must integrate with SCADA platforms, batch control systems, and enterprise resource planning (ERP) tools to support holistic plant operations.

We help clients achieve seamless integration that allows:

- Centralized monitoring of all CIP loops

- Remote access to live data and historical records

- Automatic batch documentation

- Role-based access and user authentication

Whether you are operating in a dairy plant, beverage facility, or biopharmaceutical environment, integrated automation ensures CIP is aligned with production and quality goals.

GAMP5 and Validation Support

In regulated industries, cleaning systems must be validated according to Good Automated Manufacturing Practice (GAMP5) guidelines. e2i’s development methodology supports:

- User requirements specifications (URS)

- Functional and design specifications (FS/DS)

- Installation and operational qualifications (IQ/OQ)

- Change control and audit trails

By developing automation systems with validation in mind, we help reduce project risk and ensure smooth regulatory inspections.

Real-World Results of CIP Systems Automation

Facilities that have upgraded to automated CIP systems report:

- Up to 30% reduction in water and chemical usage

- 25–40% faster cycle times

- Improved product quality through cleaner equipment

- Fewer production delays due to cleaning inefficiencies

- Streamlined validation processes with digital records

These improvements aren’t just about compliance—they’re about enabling consistent, reliable operations that support growth and quality assurance.

Final Thoughts

CIP system automation is more than a technological upgrade—it’s a strategic investment in operational excellence, compliance, and product integrity. By implementing recipe control, shared tank coordination, and comprehensive data logging, manufacturers can transform CIP from a hidden cost into a driver of efficiency and quality.

At e2i, we work closely with sanitation teams, validation engineers, and operations managers to modernize cleaning processes that scale with your business.